-->

-->

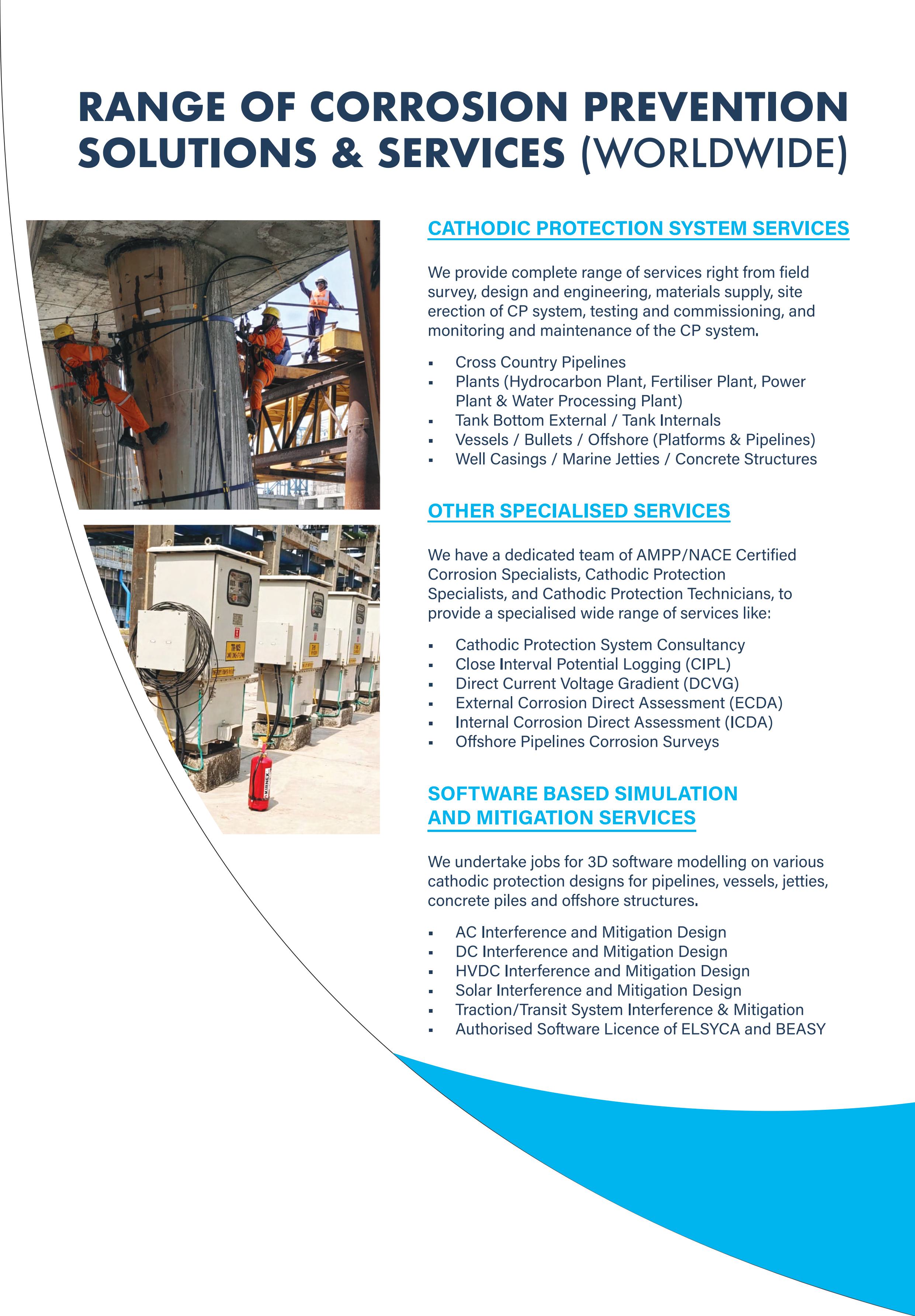

Our comprehensive Cathodic Protection EPC services ensure the integrity of pipelines, storage tanks, mounded storage vessels, and heat exchanger and small vessels, providing robust corrosion protection to maintain operational efficiency and safety of your structure against corrosion.

We deliver tailored Cathodic Protection EPC solutions to safeguard water treatment plants, water pipelines, and storage facilities, ensuring long-term infrastructure reliability against corrosion and compliance with industry standards and Aquatic Health.

Our expertise in cathodic protection extends to jetties, sheet piles, offshore structures, and harbour facilities, offering advanced solutions to combat seawater corrosion and enhance asset longevity.

We provide specialized Cathodic Protection EPC services for concrete infrastructure projects like Piles, buildings foundation, implementing effective cathodic protection systems to extend service life and ensure structural safety.

Our Cathodic Protection EPC services cater to power plants, including nuclear and renewable energy facilities, delivering critical corrosion protection to maintain the integrity and performance of essential components.

We offer full cathodic protection services, including monitoring, maintenance, and audits. Our expertise includes AC/DC interference studies and CP design validation with advanced simulations. We integrate technology and data insights for optimal solutions. Our services ensure reliable, efficient, and future-proof results.

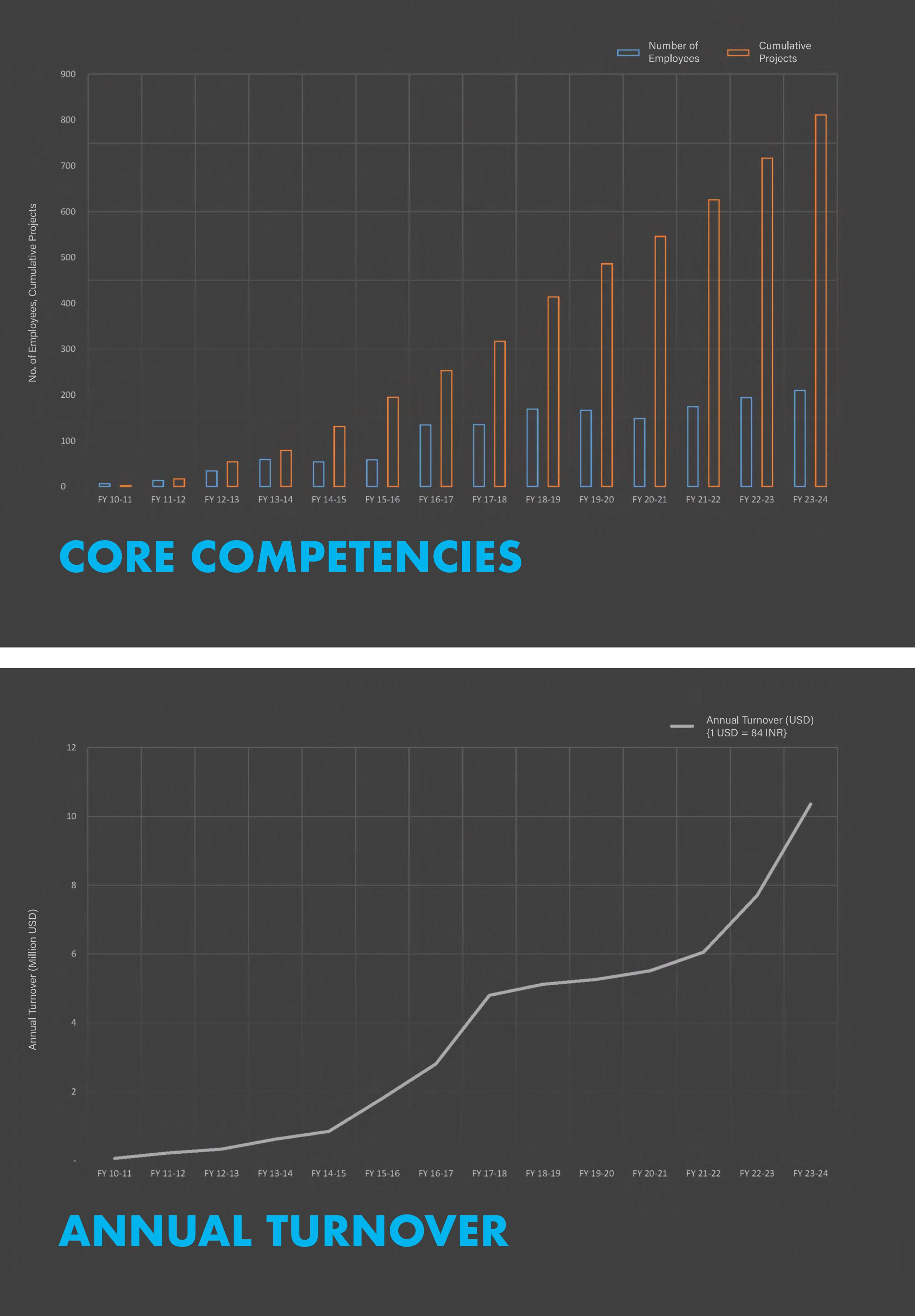

SARK EPC Projects Pvt. Ltd., established in 2011, is a leading provider of Cathodic Protection EPC Services. We offer high-quality, cost-effective solutions for corrosion prevention across various industries, including Oil and Gas, Water and Wastewater, Marine, Construction, Energy and Power, CP Solutions, and Advanced Technologies. We are your Anti-corrosion partner. We are ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certified, demonstrating our commitment to quality, environmental, and safety standards. We have successfully completed Cathodic Protection projects spanning over 12000 km of pipelines, 450+ tanks and vessels, and numerous plant piping and offshore structures. We offer end-to-end cathodic protection services, including system monitoring, routine maintenance, and detailed audits as well as specialized CP surveys. Our expertise extends to AC and DC interference studies & mitigation, and performance CP design validation through advanced simulation software. We prioritize the protection of your valuable assets with the best quality materials and services, ensuring your satisfaction and peace of mind.

SARK!!!

TODAY, TOMORROW & FOREVER